In this article, we explain how modular DOBOT cobots enable scalable, plug-and-play industrial automation, allowing companies to deploy, expand, and optimize robotic workflows with unprecedented speed, adaptability, and long-term flexibility.

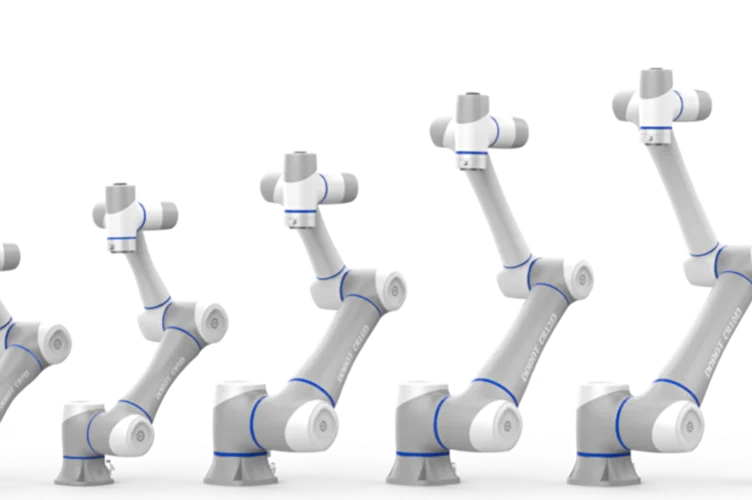

In the era of flexible automation, modular robotic systems redefine how industries scale, adapt, and innovate. DOBOT cobots represent this shift perfectly: compact, highly configurable, and capable of performing a wide spectrum of industrial tasks without the rigidity of traditional robotics. Their plug-and-play architecture allows companies to deploy automation rapidly, modify workflows on demand, and extend capabilities as production evolves. This modularity has made collaborative robots not merely tools but strategic assets—particularly in sectors where precision, safety, and adaptability matter as much as speed.

Modularity as a Growth Engine for Modern Industrial Environments

At the heart of modular cobot automation lies the principle of scalable complexity: start small, expand intelligently, and never overinvest before the need arises. This philosophy is precisely why DOBOT cobots have become a preferred choice for companies transitioning into Industry 4.0.

Below are the foundational advantages that make modular cobots essential for flexible, future-ready production environments:

- Rapid deployment with minimal infrastructure changes. Cobots can be installed on existing workstations without redesigning the shopfloor.

- High repeatability across variable tasks. Consistent 24/7 precision ensures measurable improvements in cycle times and product quality.

- Easy reconfiguration using modular end-effectors. Grippers, cameras, dispensers, screwdrivers—all attach seamlessly to expand functionality in minutes.

- Adaptability to workforce needs. Cobots assist human operators rather than replace them, improving ergonomics and reducing injury risk.

This modular foundation enables industries to evolve dynamically, ensuring automation grows in sync with production demands rather than dictating them.

Industry Applications: How DOBOT Cobots Transform Workflows

Modularity is most visible in the sheer diversity of industries adopting collaborative robotics. From electronics to agriculture, cobots serve as multifunctional platforms rather than single-purpose machines.

Below are key sectors where DOBOT cobots demonstrate exceptional versatility and measurable productivity gains:

- Electronics assembly and micro-manufacturing. Cobots perform delicate pick-and-place, soldering, and precision inspection tasks beyond human steadiness.

- Automotive and mechanical production. From component feeding to gasket application, cobots streamline repetitive processes while integrating easily with CNC machinery.

- Food and packaging industries. With hygienic attachments, cobots handle sorting, packing, and labeling without cross-contamination risks.

- Laboratory automation and pharmaceuticals. Cobots ensure sterile, accurate sample handling where consistency is more important than speed.

The result is a new generation of workflows where robotic assistance becomes the default—cleaner, faster, and significantly more reliable than fully manual methods.

Smart Integration: Simulation, Training & Lifecycle Optimization

Deploying modular cobots extends far beyond installation. Intelligent integration ensures the robotic system functions as a cohesive part of a broader digital ecosystem—predictable, measurable, and continuously improvable.

Below are the strategic components that maximize the value of modular cobot deployments:

- 3D simulation and process modeling. Digital twins help plan productivity rates, workstation layouts, and robot trajectories before hardware installation.

- Advanced operator training programs. Modular learning systems accelerate staff productivity and ensure safe, efficient cobot interaction.

- Comprehensive technical support and maintenance routines. Continuous diagnostics and predictive maintenance minimize downtime and extend hardware lifecycle.

- Flexible modernization and upgrade pathways. As needs change, cobots can be enhanced with new modules, software packages, or AI-driven guidance systems.

With these elements combined, modular cobot solutions become more than automation—they become adaptive infrastructures supporting long-term technological evolution.

Industries seeking to future-proof their operations increasingly adopt modular robotics as the foundation of scalable automation. Partnering with specialists such as robotics solutions provider Quant Robotics (https://quant-robotics.com/) ensures that DOBOT cobots are not only deployed efficiently but integrated into cohesive, high-performance ecosystems built to grow alongside the business.

Оставить ответ